- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

incoloy

Model Number:RMD-Incoloy-Alloy

Application: Industry

specifications:according to customer’s requirement

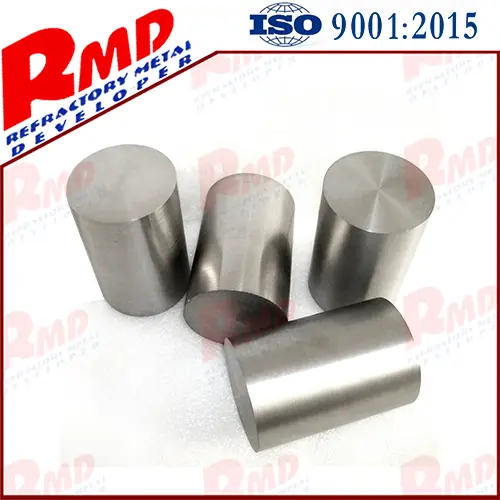

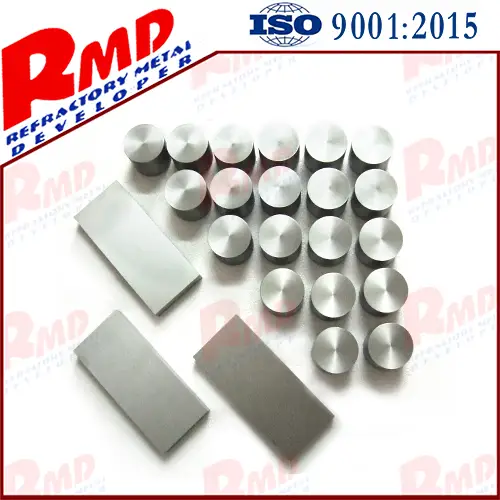

Shape:Round,plate,bar

Technique:Rolled

Grade:Incoloy 800,Incoloy 825

Weight:8.0g/cm3

Product name: ASTM Incoloy Alloy

Material:Incoloy 800,Incoloy 825

Color:sliver/Nickel nature colour

Surface:bright finish

Lead time :About 25 days

Standard:ASTM

Advantage:Excellent resistance to electrochemical corrosion and good resistance to effect of heat

Certificates: ISO 9001:2015

Product Overview:

Incoloy is a premium nickel-iron-chromium alloy renowned for its exceptional resistance to high temperatures and corrosion. With its superior performance in harsh environments, it finds extensive applications across various industries, from aerospace to chemical processing.

Product Characteristics:

- Physical Properties: It exhibits high strength, excellent oxidation resistance, and remarkable stability at elevated temperatures.

- Chemical Properties: It showcases outstanding resistance to corrosion by acids, alkalis, and other harsh chemicals.

- Mechanical Properties: It offers superior tensile strength and toughness, making it suitable for demanding industrial applications.

- Other Characteristics: It possesses good weldability and fabricability, allowing for ease of processing and customization.

Product Specifications:

| Grade | Composition | Density | Melting Point | Tensile Strength | Yield Strength |

|---|---|---|---|---|---|

| Incoloy 800 | Ni 30-35%, Fe 39.5%, Cr 19-23% | 8.11 g/cm³ | 1350°C | 520 MPa | 210 MPa |

| Incoloy 825 | Ni 38-46%, Fe 22% | 8.14 g/cm³ | 1400°C | 550 MPa | 220 MPa |

Application Fields:

Gas Turbines: It composites are utilized in the airplane business for parts in gas turbine motors, for example, turbine sharp edges, ignition chambers, and max engine thrust, because of their high temperature strength and erosion obstruction.

Substance Handling Gear: It combinations find applications in petrochemical plants for gear like reactors, heat exchangers, and channeling frameworks that expect protection from destructive synthetic substances, high temperatures, and strain.

Boilers and Intensity Exchangers: It combinations are used in power plants for evaporator parts, heat exchangers, and steam generator tubing, where protection from high temperatures and oxidation is fundamental.

Downhole Hardware: Incoloy alloy are utilized in oil and gas investigation and creation for downhole hardware, like tubing, packaging, and valves, because of their protection from destructive conditions and high-pressure conditions.

Marine Exhaust Frameworks: It composites track down applications in marine exhaust frameworks for ships and seaward stages, where they offer consumption protection from seawater, high temperatures, and acidic exhaust gases.

Corrosive Creation: It combinations are appropriate for applications in corrosive creation plants where they are utilized in hardware presented to destructive acids, like sulfuric corrosive and hydrochloric corrosive.

Heat Treatment Gear: It amalgams might be utilized in food handling hardware for heat treatment processes, like broilers, heaters, and warming components, because of their high-temperature strength and consumption opposition.

Sanitization Gear: It combinations track down applications in clinical disinfection gear, like autoclaves and sanitizers, where they give protection from high temperatures and steam erosion.

Exhaust Frameworks: It combinations are utilized in car fumes frameworks for their protection from high temperatures, oxidation, and destructive fumes gases, adding to expanded sturdiness and life span.

Quality Control:

Our Incoloy alloy goes through severe quality control measures at each phase of assembling to guarantee adherence to industry norms and determinations. We center around quality and consistency to meet the various prerequisites of our clients.

Packaging and Transportation:

We package products securely to prevent damage during transportation. Our efficient logistics network ensures timely delivery to customers worldwide, with meticulous attention to handling and storage requirements.

Certifications and Standards:

Our incoloy alloy pipe comply with international standards and certifications, including ASTM, ASME, and ISO, guaranteeing their quality and reliability for critical applications.

Customized Services:

We offer customized answers for meet explicit client prerequisites, including custom sizes, shapes, and arrangements custom fitted to individual necessities.

FAQ:

Q: What are the primary advantages of using it?

A: It offers exceptional resistance to high temperatures and corrosion, making it ideal for demanding industrial environments.

Q: Can incoloy alloy pipe be welded easily?

A: Yes, Incoloy exhibits good weldability, allowing for ease of fabrication and joining.

RMD Highlights:

RMD is a leading supplier of premium Incoloy products, operating from a GMP-certified facility with extensive inventory and complete certifications. Our professional after-sales team ensures prompt assistance and support, offering a one-stop solution for all your Incoloy requirements. With OEM support, fast delivery, and secure packaging, RMD is your trusted partner for superior quality Incoloy products. For inquiries or customized orders, please contact us at rmd1994@yeah.net.

With RMD, choose excellence in Incoloy – your reliable partner for superior performance and reliability in challenging environments.

YOU MAY LIKE

GH-superalloy

Brand Name:RMD<br>Model Number:RMD-GH-Superalloy<br>Application: Industry<br>specifications:according to customer’s requirement<br>Shape:Round,plate,bar<br>Technique:Rolled<br>Grade:GH 2132,GH 4145,GH 4169<br>Weight:8.8g/cm3<br>Product name: ASTM GH Superalloy<br>Material:GH 2132,GH 4145,GH 4169<br>Color:sliver/Nickel nature colour<br>Surface:bright finish<br>Lead time :About 25 days<br>Standard:ASTM<br>Advantage:Excellent resistance to electrochemical corrosion and good resistance to effect of heat<br>Certificates: ISO 9001:2015<br>

View More

expansion alloy

Brand Name:RMD<br>Model Number:RMD-Expansion-Alloy<br>Application: Industry<br>specifications:according to customer’s requirement<br>Shape:Round,plate,bar<br>Technique:Rolled<br>Grade:4j29,4j32,4j36<br>Weight:7~8.5g/cm3<br>Product name: ASTM Expansion Alloy<br>Material:4j29,4j32,4j36<br>Color:sliver/Nickel nature colour<br>Surface:bright finish<br>Lead time :About 25 days<br>Standard:ASTM<br>Advantage:Excellent resistance to electrochemical corrosion and good resistance to effect of heat<br>Certificates: ISO 9001:2015<br>

View More

nickel alloy strip

Brand Name:RMD<br>Model Number:RMD-Nickel-strip<br>Application:Caustic handling equipment,Food processing equipment etc<br>Thickness:0.015-6mm<br>Shape:Plate,sheet<br>Width:according to customer's requirement<br>Technique:Rolled<br>Grade:N6,NUS N02200<br>Weight:8.9g/cm3<br>Product name: ASTM B162 Nickel strip<br>Material: N6,NUS N02200<br>Color:sliver/Nickel nature colour<br>Surface:bright finish<br>Lead time :About 25 days<br>Standard:ASTM B162<br>Advantage:Excellent resistance to electrochemical corrosion and good resistance to effect of heat<br>Certificates: ISO 9001:2015<br>

View More

nickel alloy rod

Brand Name:RMD<br>Model Number:RMD-Nickel-Rod<br>Application: Industry<br>Diameter:3.0-60mm<br>Shape:Round<br>Length:MAX:1500mm<br>Technique:Rolled<br>Grade:N6,Inconel 600,Inconel 625<br>Weight:8.9g/cm3<br>Product name: ASTM B160 Nickel Rod<br>Material:N6,Inconel 600,Inconel 625<br>Color:sliver/Nickel nature colour<br>Surface:bright finish<br>Lead time :About 25 days<br>Standard:ASTM B160<br>Advantage:Excellent resistance to electrochemical corrosion and good resistance to effect of heat<br>Certificates: ISO 9001:2015<br>

View More

Nickel Base Alloy

Brand Name:RMD<br>Model Number:RMD-Nickel-Alloy<br>Application: Industry<br>specifications:according to customer’s requirement<br>Shape:Round,plate,bar<br>Technique:Rolled<br>Grade:Inconel,GH,Monel,4J33,Incoloy<br>Weight:7~8.5g/cm3<br>Product name: ASTM Nickel Alloy<br>Material:Inconel,GH,Monel,4J33,Incoloy<br>Color:sliver/Nickel nature colour<br>Surface:bright finish<br>Lead time :About 25 days<br>Standard:ASTM<br>Advantage:Excellent resistance to electrochemical corrosion and good resistance to effect of heat<br>Certificates: ISO 9001:2015<br>

View More

thin nickel foil

Brand Name:RMD<br>Model Number:RMD-Nickel-Foil<br>Application:Caustic handling equipment,Food processing equipment etc<br>Thickness:0.015-6mm<br>Shape:Plate,sheet<br>Width:according to customer's requirement<br>Technique:Rolled<br>Grade:N6,NUS N02200<br>Weight:8.9g/cm3<br>Product name: ASTM B162 Nickel Foil<br>Material: N6,NUS N02200<br>Color:sliver/Nickel nature colour<br>Surface:bright finish<br>Lead time :About 25 days<br>Standard:ASTM B162<br>Advantage:Excellent resistance to electrochemical corrosion and good resistance to effect of heat<br>Certificates: ISO 9001:2015<br>

View More

pure nickel rod

Brand Name:RMD<br>Model Number:RMD-Nickel-Rod<br>Application: Industry<br>Diameter:3.0-60mm<br>Shape:Round<br>Length:MAX:1500mm<br>Technique:Rolled<br>Grade:N6,NUS N02200<br>Weight:8.9g/cm3<br>Product name: ASTM B160 Nickel Rod<br>Material:N6,NUS N02200<br>Color:sliver/Nickel nature colour<br>Surface:bright finish<br>Lead time :About 25 days<br>Standard:ASTM B160<br>Advantage:Excellent resistance to electrochemical corrosion and good resistance to effect of heat<br>Certificates: ISO 9001:2015<br>

View More

Nickel Bar

Brand Name:RMD<br>Model Number:RMD-Nickel-Bar<br>Application: Industry<br>Diameter:3.0-60mm<br>Shape:Round<br>Length:MAX:1500mm<br>Technique:Rolled<br>Grade:N6,NUS N02200<br>Weight:8.9g/cm3<br>Product name: ASTM B160 Nickel Bar<br>Material:N6,NUS N02200<br>Color:sliver/Nickel nature colour<br>Surface:bright finish<br>Lead time :About 25 days<br>Standard:ASTM B160<br>Advantage:Excellent resistance to electrochemical corrosion and good resistance to effect of heat<br>Certificates: ISO 9001:2015<br>

View More