- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

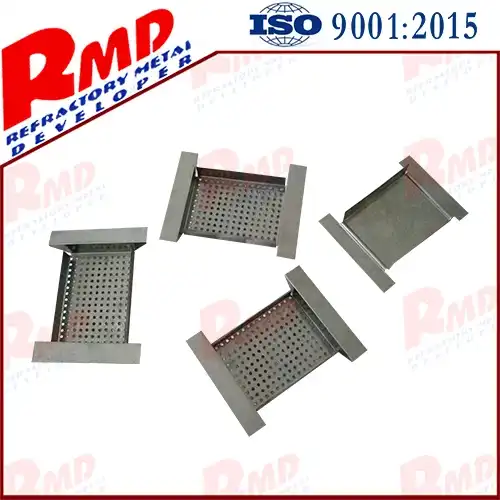

Tungsten Machining Components

Model Number:RMD-W-Machining-Components

Application:applied in high temperature vacuum furnace melting environment such as sapphire growing furnace,etc

Specifications: according to customer’s requirementm

Grade:W1

Weight:19.3g/cm3

Product name: Tungsten Machining Components

Material: W1

Color:sliver/Tungsten nature colour

Surface:Alkali cleaning surface/Grinded surface

Lead time :About 25 days

Standard:ASTM

Advantage:High melting point,High-density,Excellent resistance to electrochemical corrosion

Certificates: ISO 9001:2015

Product Overview:

Tungsten Machining Components, engineered by RMD, are precision-crafted parts designed to meet the demanding requirements of various industrial applications. Renowned for its exceptional strength, durability, and resistance to extreme conditions, tungsten stands as a premier choice for machining components across industries. RMD delivers top-notch tungsten components tailored to diverse needs, ensuring optimal performance and reliability in critical operations.

Product Characteristics:

· Physical Properties: High density, excellent thermal conductivity, superior hardness, and low thermal expansion.

· Chemical Properties: Exceptional resistance to corrosion, acids, and alkalis, ensuring longevity and reliability.

· Mechanical Properties: Outstanding strength, toughness, and wear resistance, enabling reliable performance under challenging conditions.

· High Hardness and Wear Resistance: Tungsten alloys exhibit exceptional hardness and wear resistance, making them ideal materials for machining components subjected to high stresses, abrasive wear, and cutting forces. These properties ensure prolonged tool life, reduced wear rates, and enhanced machining precision in challenging manufacturing processes.

· Superior Machinability: Despite their high hardness, tungsten alloys can be precisely machined to tight tolerances and intricate geometries using advanced machining techniques such as milling, turning, drilling, and grinding. Their machinability allows for the production of complex components with fine surface finishes, sharp edges, and intricate features required in various manufacturing sectors, including aerospace, automotive, electronics, and medical device manufacturing.

Benefits:

· Exceptional hardness and wear resistance for extended tool life and reduced machining costs.

· Superior thermal stability enables high-speed machining and precise dimensional control.

· Excellent machinability allows for the production of complex components with tight tolerances.

· Chemical inertness ensures durability and stability in corrosive machining environments.

· Customization options provide flexibility to meet diverse application requirements and performance criteria.

Product Specifications:

|

Product Name |

Dimensions |

Tolerance |

Surface Finish |

|

Tungsten Rods |

Diameter: 2-100mm |

+/- 0.05mm |

Ground or Polished |

|

Tungsten Plates |

Thickness: 0.1-50mm |

+/- 0.1mm |

Ground or Polished |

|

Tungsten Tubes |

OD: 1-50mm |

+/- 0.05mm |

Ground or Polished |

|

Tungsten Crucibles |

Custom Sizes |

Custom Tolerance |

Smooth or Textured |

Application Fields:

Tungsten machining services find extensive applications in industries such as aerospace, automotive, electronics, energy, medical, and defense. These components serve critical roles in equipment manufacturing, high-temperature furnaces, electrical contacts, radiation shielding, and more.

Quality Control:

RMD employs stringent quality control measures throughout the manufacturing process to ensure the highest standards of precision, reliability, and performance. Our components undergo rigorous inspection and testing to meet or exceed customer expectations.

Packaging and Transportation:

We prioritize the safe and secure packaging of our Machined Tungsten Parts to prevent damage during transit. Each product is carefully packed to withstand handling and transportation challenges, ensuring it reaches its destination intact and ready for use.

Relevant Certifications and Standards:

Our Tungsten machining services comply with industry-leading certifications and standards, including ISO 9001:2015, ensuring consistency, reliability, and customer satisfaction.

Customized Services:

RMD offers tailored solutions to meet specific customer requirements, including custom dimensions, tolerances, surface finishes, and configurations. Our experienced team works closely with clients to deliver bespoke tungsten components that perfectly align with their applications.

FAQ:

Q: Can you provide custom dimensions for tungsten components?

A: Yes, we offer customized machining services to meet individual specifications and requirements.

Q: What certifications do your tungsten components have?

A: Our products adhere to ISO 9001:2015 standards, guaranteeing quality and reliability.

RMD Highlights:

RMD is a leading supplier of tungsten machining components, boasting a GMP-certified factory, extensive inventory, and comprehensive certifications. Backed by a professional after-sales team, we offer one-stop solutions, OEM support, and fast delivery worldwide. With meticulous attention to detail, tight packaging, and a commitment to customer satisfaction, RMD is your trusted partner for premium tungsten components. For inquiries or orders, contact us at rmd1994@yeah.net.

conclusion

In conclusion, RMD's Machined Tungsten Parts stand as the epitome of quality, reliability, and performance, catering to the diverse needs of professional buyers and global dealers across industries.

YOU MAY LIKE

Niobium Machining Components

Brand Name:RMD<br> Model Number:RMD-Nb-Machining- Components<br> Application:chemical industry,superconductive material,high temperature metallurgy<br> Specifications: according to customer’s requirementm<br> Grade:Nb1<br> Weight:8.57g/cm3<br> Product name:Niobium Machining Components<br> Material: Nb1<br> Color:sliver/Niobium nature colour<br> Surface:bright finish<br> Lead time :About 25 days<br> Standard:ATSTM<br> Advantage:Excellent resistance to electrochemical corrosion,Good cold processability<br> Certificates: ISO 9001:2015<br>

View More

Tantalum Machining Parts

Brand Name:RMD<br> Model Number:RMD-Ta-Machining -Parts<br> Application:used for electronics,high temperature using parts,reaction containers,ect.<br> Specifications: according to customer’s requirementm<br> Grade:Ta1,Ta2.5W,Ta10w,TaNb3,RO5200,RO5252,RO5255<br> Weight:16.6g/cm3<br> Product name: Tantalum Machining Parts<br> Material: Ta1,Ta2.5W,Ta10w,TaNb3,RO5200,RO5252,RO5255<br> Color:sliver/Tantalum nature colour<br> Surface:polished<br> Lead time :About 25 days<br> Standard:ASTM B521<br> Advantage:High Ductility,Excellent resistance to electrochemical corrosion<br> Certificates: ISO 9001:2015<br>

View More

Tantalum boat

Brand Name:RMD<br> Model Number:RMD-Ta-boat<br> Application:used for electronics,high temperature using parts,reaction containers,ect.<br> Specifications: according to customer’s requirementm<br> Grade:Ta1,Ta2.5W,Ta10w,TaNb3,RO5200,RO5252,RO5255<br> Weight:16.6g/cm3<br> Product name: Tantalum boat<br> Material: Ta1,Ta2.5W,Ta10w,TaNb3,RO5200,RO5252,RO5255<br> Color:sliver/Tantalum nature colour<br> Surface:polished<br> Lead time :About 25 days<br> Standard:ASTM B521<br> Advantage:High Ductility,Excellent resistance to electrochemical corrosion<br> Certificates: ISO 9001:2015<br>

View More

Tantalum Machining Components

Brand Name:RMD<br> Model Number:RMD-Ta-Machining-Components<br> Application:used for electronics,high temperature using parts,reaction containers,ect.<br> Specifications: according to customer’s requirementm<br> Grade:Ta1,Ta2.5W,Ta10w,TaNb3,RO5200,RO5252,RO5255<br> Weight:16.6g/cm3<br> Product name: Tantalum Machining Components<br> Material: Ta1,Ta2.5W,Ta10w,TaNb3,RO5200,RO5252,RO5255<br> Color:sliver/Tantalum nature colour<br> Surface:polished<br> Lead time :About 25 days<br> Standard:ASTM B521<br> Advantage:High Ductility,Excellent resistance to electrochemical corrosion<br> Certificates: ISO 9001:2015<br>

View More

Molybdenum parts

Brand Name:RMD<br> Model Number:RMD-Mo-parts<br> Application:Hook of the lamp/Core of the lamp filament/Grid for the vacuum tube/Leader,supporter of the lamp/Heater for the high temperature furnace/Electrode/Making strip<br> Specifications: according to customer’s requirementm<br> Grade:Mo1<br> Weight:10.2g/cm3<br> Product name: Molybdenum parts<br> Material: Mo1<br> Color:sliver/Molybdenum nature colour<br> Surface:Polished surface/Grinded surface<br> Lead time :About 25 days<br> Standard:ASTM<br> Advantage:High melting point,Excellent resistance to electrochemical corrosion, Good electrical conductivity<br> Certificates: ISO 9001:2015<br>

View More

Molybdenum Boat

Brand Name:RMD<br> Model Number:RMD-Mo-boat<br> Application:Hook of the lamp/Core of the lamp filament/Grid for the vacuum tube/Leader,supporter of the lamp/Heater for the high temperature furnace/Electrode/Making strip<br> Specifications: according to customer’s requirementm<br> Grade:Mo1<br> Weight:10.2g/cm3<br> Product name: Molybdenum boat<br> Material: Mo1<br> Color:sliver/Molybdenum nature colour<br> Surface:Polished surface/Grinded surface<br> Lead time :About 25 days<br> Standard:ASTM<br> Advantage:High melting point,Excellent resistance to electrochemical corrosion, Good electrical conductivity<br> Certificates: ISO 9001:2015<br>

View More

Molybdenum Crucible

Brand Name:RMD<br> Model Number:RMD-Mo-Crucible<br> Application:Hook of the lamp/Core of the lamp filament/Grid for the vacuum tube/Leader,supporter of the lamp/Heater for the high temperature furnace/Electrode/Making strip<br> Specifications: according to customer’s requirementm<br> Grade:Mo1<br> Weight:10.2g/cm3<br> Product name: Molybdenum Crucible<br> Material: Mo1<br> Color:sliver/Molybdenum nature colour<br> Surface:Polished surface/Grinded surface<br> Lead time :About 25 days<br> Standard:ASTM<br> Advantage:High melting point,Excellent resistance to electrochemical corrosion, Good electrical conductivity<br> Certificates: ISO 9001:2015<br>

View More

Tungsten Boat

Brand Name:RMD<br> Model Number:RMD-W-boat<br> Application:applied in high temperature vacuum furnace melting environment such as sapphire growing furnace,etc<br> Specifications: according to customer’s requirementm<br> Grade:W1<br> Weight:19.3g/cm3<br> Product name: ASTM Tungsten boat<br> Material: W1<br> Color:sliver/Tungsten nature colour<br> Surface:Alkali cleaning surface/Grinded surface<br> Lead time :About 25 days<br> Standard:ASTM<br> Advantage:High melting point,High-density,Excellent resistance to electrochemical corrosion<br> Certificates: ISO 9001:2015<br>

View More