- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

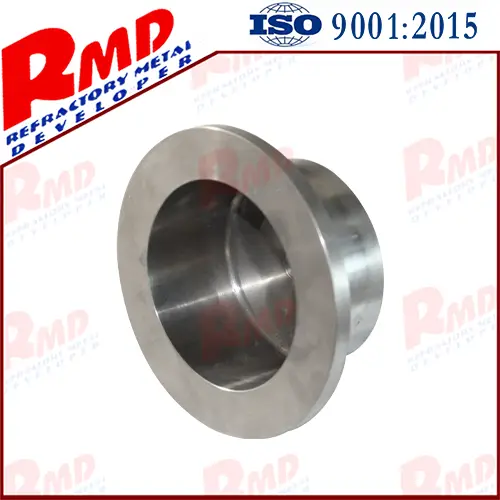

nickel Crucible

Model Number:RMD-Nickel- Crucible

Application: Industry

Specifications: according to customer’s requirementm

Grade:N6,NUS N02200

Weight:8.9g/cm3

Product name:Nickel Crucible

Material:N6,NUS N02200

Color:sliver/Nickel nature colour

Surface:bright finish

Lead time :About 25 days

Standard:ASTM B161

Advantage:Excellent resistance to electrochemical corrosion and good resistance to effect of heat

Certificates: ISO 9001:2015

Product Overview:

Welcome to RMD, your trusted partner for high-quality nickel crucibles. Our nickel crucibles are meticulously crafted to meet the demanding needs of various industries, ensuring optimal performance and reliability. With our commitment to excellence and innovation, we provide superior products that exceed expectations. Explore the exceptional features and applications of our nickel crucibles below.

Product Characteristics:

Physical Properties: Our nickel crucibles exhibit excellent thermal conductivity, corrosion resistance, and high melting point, making them ideal for withstanding extreme temperatures and harsh environments.

Chemical Properties: With exceptional chemical stability, our nickel crucibles ensure purity and integrity during chemical processes, minimizing contamination and ensuring accurate results.

Mechanical Properties: Robust and durable, our nickel crucibles maintain structural integrity under pressure, offering long-lasting performance in demanding applications.

Other Characteristics: Our nickel crucibles are non-magnetic, non-toxic, and environmentally friendly, meeting the highest safety and regulatory standards.

Key Features:

High Temperature Resistance: nickel crucibles are competent of withstanding tall temperatures up to 1,450°C (2,642°F) or higher without misshaping, dissolving, or responding with the substance, making them appropriate for utilize in high-temperature applications such as metal softening, glass generation, and ceramic processing.

Corrosion Resistance: Nickel-based amalgams offer fabulous resistance to erosion from acids, antacids, liquid salts, and other destructive substances, guaranteeing the judgment and life span of the pot indeed in unforgiving chemical environments.

Thermal Solidness: Nickel pots show tall warm solidness and conductivity, permitting for uniform warming and proficient warm exchange to the substance, guaranteeing steady temperature conveyance and minimizing warm angles amid warming and cooling processes.

Purity and Dormancy: nickel crucibles are made from high-purity materials to minimize defilement and chemical interaction with the substances being prepared, guaranteeing exact investigation and reproducible comes about in applications such as metallurgy, spectroscopy, and materials research.

Durability and Life span: nickel crucibles are vigorous and strong, competent of persevering rehashed warming and cooling cycles without corruption or misfortune of mechanical astuteness, giving dependable execution and long benefit life in requesting mechanical and research facility situations.

Application Fields:

Metallurgy

Chemical industry

Research laboratories

Semiconductor manufacturing

Aerospace industry

Metallurgy: nickel box are commonly used in metallurgical processes for melting, alloying, and refining metals and alloys, including steelmaking, non-ferrous metal production, and powder metallurgy applications.

Chemical Synthesis: Nickel crucibles find applications in chemical laboratories and research facilities for conducting reactions, synthesizing compounds, and performing chemical analyses under controlled conditions, where purity, inertness, and high-temperature resistance are essential.

Materials Research: Nickel crucibles are utilized in materials science and research laboratories for studying phase transformations, crystal growth, and thermal behavior of materials through techniques such as thermal analysis, crystal growth, and solid-state reactions.

Glass and Ceramics: Nickel crucibles are employed in glassmaking and ceramic processing industries for melting, fusing, and forming glass and ceramic materials at high temperatures, including glassblowing, glass casting, and ceramic sintering applications.

Semiconductor Manufacturing: Nickel crucibles are used in semiconductor fabrication processes for melting and annealing semiconductor materials such as silicon, gallium arsenide, and indium phosphide, where precise temperature control and contamination-free processing are critical.

Quality Control:

At RMD, quality is our top priority. Our nickel crucibles undergo rigorous quality control measures, including inspection, testing, and certification, to ensure superior performance and reliability in every application.

Packaging and Transportation:

We understand the importance of safe and efficient packaging and transportation. Our nickel box are carefully packaged to prevent damage during transit and ensure prompt delivery to your doorstep.

Relevant Certifications and Standards:

Our nickel crucibles meet the highest industry standards and certifications, including ISO 9001 and ASTM, ensuring compliance and reliability in diverse applications.

Customized Services:

We offer customized solutions to meet your specific requirements, including size, shape, and material composition, ensuring optimal performance and compatibility with your processes.

RMD Highlights:

RMD is your premier nickel crucible supplier, offering:

· GMP factory with large inventory

· Complete certifications and standards compliance

· Professional after-sales team

· One-stop service for all your needs

· OEM support for customized solutions

· Fast delivery and tight packaging

If you're seeking top-quality nickel crucibles for your applications, contact us at rmd1994@yeah.net. Experience the RMD difference today!

YOU MAY LIKE

Molybdenum Holder

Brand Name:RMD<br> Model Number:RMD-Mo-Holder<br> Application:Hook of the lamp/Core of the lamp filament/Grid for the vacuum tube/Leader,supporter of the lamp/Heater for the high temperature furnace/Electrode/Making strip<br> Specifications: according to customer’s requirementm<br> Grade:Mo1<br> Weight:10.2g/cm3<br> Product name: Molybdenum Holder<br> Material: Mo1<br> Color:sliver/Molybdenum nature colour<br> Surface:Polished surface/Grinded surface<br> Lead time :About 25 days<br> Standard:ASTM<br> Advantage:High melting point,Excellent resistance to electrochemical corrosion, Good electrical conductivity<br> Certificates: ISO 9001:2015<br>

View More

Molybdenum Bolt

Brand Name:RMD<br> Model Number:RMD-Mo-Bolt<br> Application:Hook of the lamp/Core of the lamp filament/Grid for the vacuum tube/Leader,supporter of the lamp/Heater for the high temperature furnace/Electrode/Making strip<br> Specifications: according to customer’s requirementm<br> Grade:Mo1<br> Weight:10.2g/cm3<br> Product name: Molybdenum Bolt<br> Material: Mo1<br> Color:sliver/Molybdenum nature colour<br> Surface:Polished surface/Grinded surface<br> Lead time :About 25 days<br> Standard:ASTM<br> Advantage:High melting point,Excellent resistance to electrochemical corrosion, Good electrical conductivity<br> Certificates: ISO 9001:2015<br>

View More

Niobium Machining Components

Brand Name:RMD<br> Model Number:RMD-Nb-Machining- Components<br> Application:chemical industry,superconductive material,high temperature metallurgy<br> Specifications: according to customer’s requirementm<br> Grade:Nb1<br> Weight:8.57g/cm3<br> Product name:Niobium Machining Components<br> Material: Nb1<br> Color:sliver/Niobium nature colour<br> Surface:bright finish<br> Lead time :About 25 days<br> Standard:ATSTM<br> Advantage:Excellent resistance to electrochemical corrosion,Good cold processability<br> Certificates: ISO 9001:2015<br>

View More

Nickel Machining Components

Brand Name:RMD<br> Model Number:RMD-Nickel-Machining- Components<br> Application: Industry<br> Specifications: according to customer’s requirementm<br> Grade:N6,NUS N02200<br> Weight:8.9g/cm3<br> Product name:Nickel Machining Components<br> Material:N6,NUS N02200<br> Color:sliver/Nickel nature colour<br> Surface:bright finish<br> Lead time :About 25 days<br> Standard:ASTM B161<br> Advantage:Excellent resistance to electrochemical corrosion and good resistance to effect of heat<br> Certificates: ISO 9001:2015<br>

View More

Tantalum boat

Brand Name:RMD<br> Model Number:RMD-Ta-boat<br> Application:used for electronics,high temperature using parts,reaction containers,ect.<br> Specifications: according to customer’s requirementm<br> Grade:Ta1,Ta2.5W,Ta10w,TaNb3,RO5200,RO5252,RO5255<br> Weight:16.6g/cm3<br> Product name: Tantalum boat<br> Material: Ta1,Ta2.5W,Ta10w,TaNb3,RO5200,RO5252,RO5255<br> Color:sliver/Tantalum nature colour<br> Surface:polished<br> Lead time :About 25 days<br> Standard:ASTM B521<br> Advantage:High Ductility,Excellent resistance to electrochemical corrosion<br> Certificates: ISO 9001:2015<br>

View More

Tantalum Machining Components

Brand Name:RMD<br> Model Number:RMD-Ta-Machining-Components<br> Application:used for electronics,high temperature using parts,reaction containers,ect.<br> Specifications: according to customer’s requirementm<br> Grade:Ta1,Ta2.5W,Ta10w,TaNb3,RO5200,RO5252,RO5255<br> Weight:16.6g/cm3<br> Product name: Tantalum Machining Components<br> Material: Ta1,Ta2.5W,Ta10w,TaNb3,RO5200,RO5252,RO5255<br> Color:sliver/Tantalum nature colour<br> Surface:polished<br> Lead time :About 25 days<br> Standard:ASTM B521<br> Advantage:High Ductility,Excellent resistance to electrochemical corrosion<br> Certificates: ISO 9001:2015<br>

View More

Molybdenum Heating Elements

Brand Name:RMD<br> Model Number:RMD-Mo-Heating- Elements<br> Application:Hook of the lamp/Core of the lamp filament/Grid for the vacuum tube/Leader,supporter of the lamp/Heater for the high temperature furnace/Electrode/Making strip<br> Specifications: according to customer’s requirementm<br> Grade:Mo1<br> Weight:10.2g/cm3<br> Product name: Molybdenum Heating Elements<br> Material: Mo1<br> Color:sliver/Molybdenum nature colour<br> Surface:Polished surface/Grinded surface<br> Lead time :About 25 days<br> Standard:ASTM<br> Advantage:High melting point,Excellent resistance to electrochemical corrosion, Good electrical conductivity<br> Certificates: ISO 9001:2015<br>

View More

Molybdenum parts

Brand Name:RMD<br> Model Number:RMD-Mo-parts<br> Application:Hook of the lamp/Core of the lamp filament/Grid for the vacuum tube/Leader,supporter of the lamp/Heater for the high temperature furnace/Electrode/Making strip<br> Specifications: according to customer’s requirementm<br> Grade:Mo1<br> Weight:10.2g/cm3<br> Product name: Molybdenum parts<br> Material: Mo1<br> Color:sliver/Molybdenum nature colour<br> Surface:Polished surface/Grinded surface<br> Lead time :About 25 days<br> Standard:ASTM<br> Advantage:High melting point,Excellent resistance to electrochemical corrosion, Good electrical conductivity<br> Certificates: ISO 9001:2015<br>

View More