- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

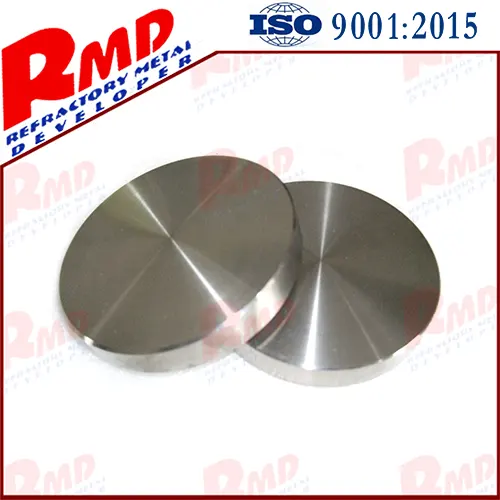

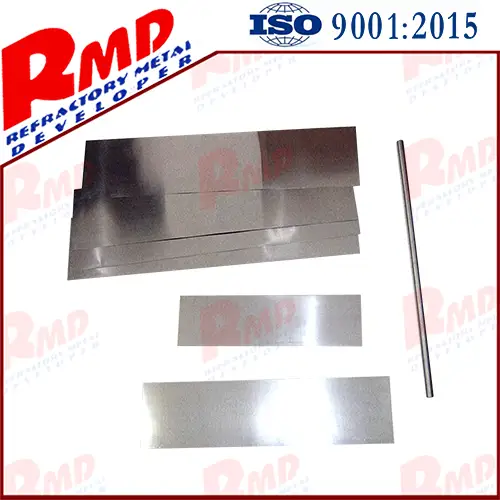

Round And Square And Any Shape You Want Ta Material Tantalum Rotating Sputtering Target Block

2024-01-05 18:00:06

Because of its excellent performance widely used in special industries such as sputtering targets and aerospace. Tantalum target is mainly used to make the barrier layer to prevent the mutual diffusion of aluminum or copper and silicon, under normal circumstances the higher the purity of tantalum target, the formation of the barrier layer texture and microstructure more uniform, The better the performance. In order to improve the refining capacity to obtain high-purity tantalum target, electron beam smelting (EBM) is used to produce high purity tantalum. However, the EBM ingot contains some coarse columnar grains with dimensions up to the centimeter level. Therefore, EBM tantalum is not directly used for industrial sputtering target, but through such as forging, rolling, annealing and secondary annealing and a series of processes to prepare weaker texture, fine grain and uniform organization.

Based on this, the method of obtaining uniform grain size and controlling texture by rolling and forging annealing is used in a large amount, and the method of changing the high purity tantalum plate rolling path to obtain the optimum microstructure and texture distribution Also proposed, such as the use of rolling, symmetrical rolling and asymmetric rolling. Recently, the research group studied the microstructure and texture evolution of tantalum under 135 ° cross rolling. The results show that the deformation microstructure, dislocation morphology and texture distribution can be changed by changing the amount of rolling deformation, which can affect the subsequent annealing and recrystallization process. It is an effective means to control the microstructure and texture of the material. However, the problem of microstructure and texture gradient evolution of tantalum target along the thickness direction is rarely studied.