- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

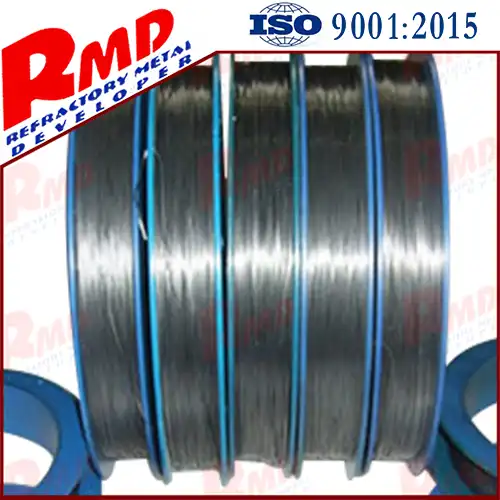

Molybdenum Wires (Mo Wires) Can Be Grouped Into Black And White Molybdenum Wires Or Spray And Wire Cutting Molybdenum Wires.

2024-01-05 18:00:06

Molybdenum with properties similar to tungsten, molybdenum has a high strength to weight ratio, is not subject to hydrogen embrittlement. The molybdenum wire mesh is often purposeful in the metallurgical applications and chemical operations. It is extensively utilized in the applications that require aggressive heating like aircraft parts, electrical joints and commercial motors.

Molybdenum wires (mo wires) can be grouped into black and white molybdenum wires or spray and wire cutting molybdenum wires.

Moly wire is used as hot cathode or gate in electron tube, sealing parts of glass and ceramics, electronic-vacuum and electric light source parts, and high temperature heaters. It can be also employed to roll molybdenum foil and remake small specification molybdenum wires.

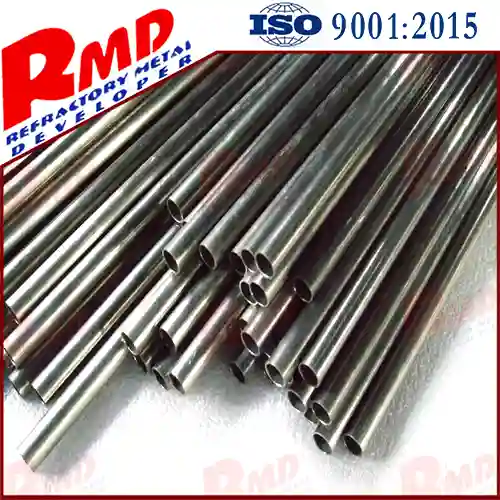

Molybdenum Wire

Circles the filament core, the support wire, the lead-out wire, the electronics grid and so on.

The support silk, the lead-out wire guide rod, the electricity vacuum components, the heater element, and the gives off heat the material and so on.

For EMD wire cut, high tensile strength, small elongation ratio, good stability, high cutting precision

Black molybdenum wire

Black molybdenum wire used in cored wire, cut wire, hook, side bar, strut and pinout, gate wire and other parts with requirements of elongation

White molybdenum wire

White molybdenum wire used for electric vacuum, electric light source industry for cored wire, molybdenum needle, strut, pinout, etc