- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Do You Know What Are The Applications Of Tantalum Sputtering Target?

2024-01-05 18:00:06

Tantalum sputtering targets are a type of material used in the sputtering process to deposit thin films of tantalum onto substrates. The sputtering process involves bombarding a target material with high-energy ions, which eject atoms from the surface of the target. These ejected atoms then deposit onto the substrate, forming a thin film.

Tantalum sputtering targets are used in various industrial applications for the deposition of thin films of tantalum onto substrates. The primary applications include:

1. Semiconductor Industry: It is extensively used in the semiconductor industry for the deposition of thin films of tantalum onto silicon wafers. These films are used as diffusion barriers, as well as for the fabrication of capacitors and other electronic components.

2. Hard Coatings: It’s used to deposit hard coatings on cutting tools, machine parts, and other surfaces that require excellent wear resistance.

3. Decorative Coatings: It’s used in the production of decorative coatings on glass, ceramics, and other materials. These coatings provide a high-end appearance and enhance the scratch resistance of the surface.

4. Solar Cells: It’s used to deposit thin films of tantalum onto solar cells. These films improve the efficiency of the cells and provide a protective barrier against environmental factors.

5. Medical Devices: It’s used to produce bio-compatible coatings on medical implants, such as pacemakers, hip replacements, and dental implants. These coatings enhance the durability and biocompatibility of the implants.

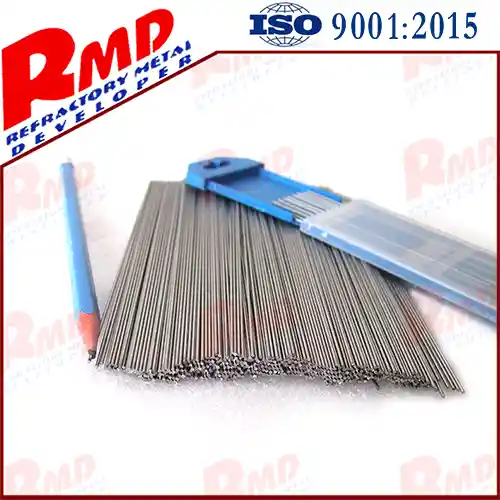

Tantalum targets are made from high-purity tantalum and are typically available in various shapes and sizes, including cylindrical, rectangular, and circular. The size and shape of the target depend on the specific sputtering system being used and the size of the substrate being coated.

Overall, tantalum sputtering targets are a critical component in many industries, where thin film deposition is required, and the high-performance properties of tantalum are needed.